When considering a sealing for your solution it is not just the level of sealing that is relevant but also the type of sealing. The IP rating tells you the level of protection, and the type of sealing tells you which part of the component it stands for. These terms help you determine the suitability of the component for your application and environment.

There are three types: panel sealed, fully sealed, or super sealed HMI. However, they are not standardized so they can vary from manufacturer to manufacturer.

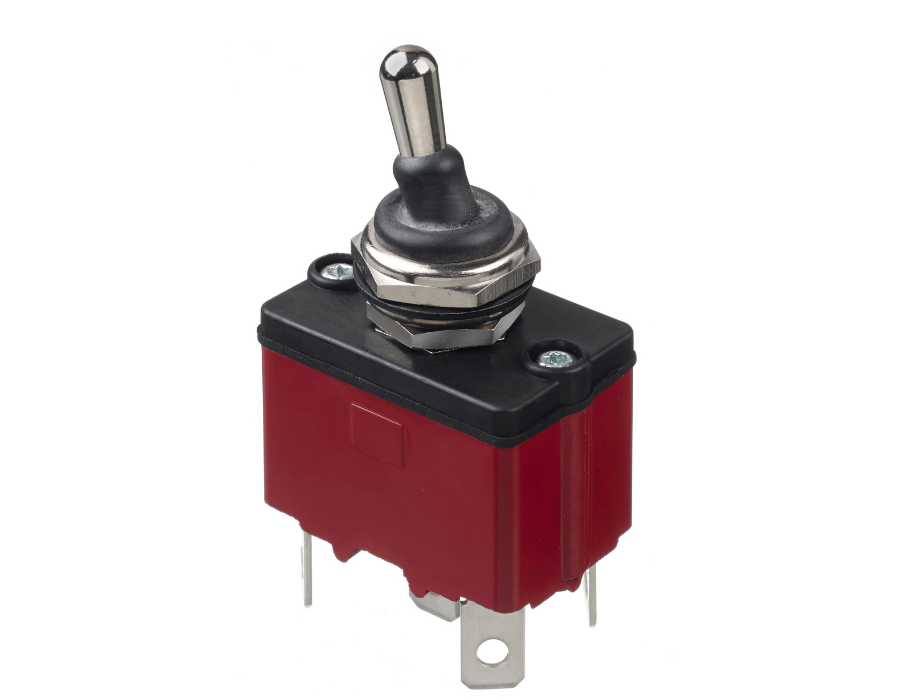

PANEL SEALED

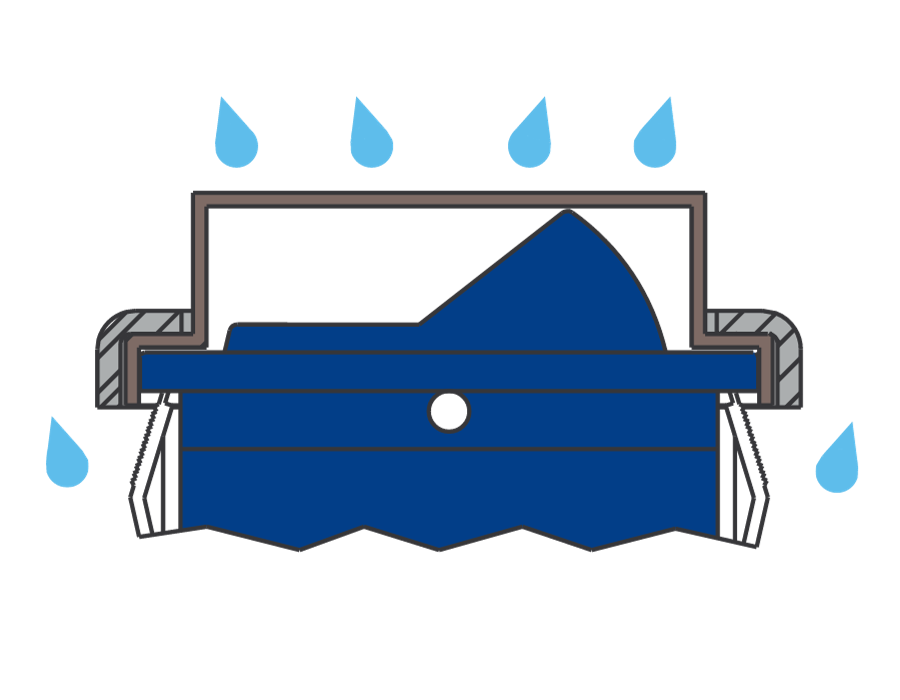

A panel sealing typically refers to a component that is sealed from the front panel, which protects the HMI from ingress coming from the outside. Panel-sealed components usually have a sealing gasket or an O-ring to create a barrier between the component and the panel, thereby preventing contaminants from entering the gap between the component and the panel. Panel sealing is often for low to medium risk of ingress and/or for applications that are not safety-critical.

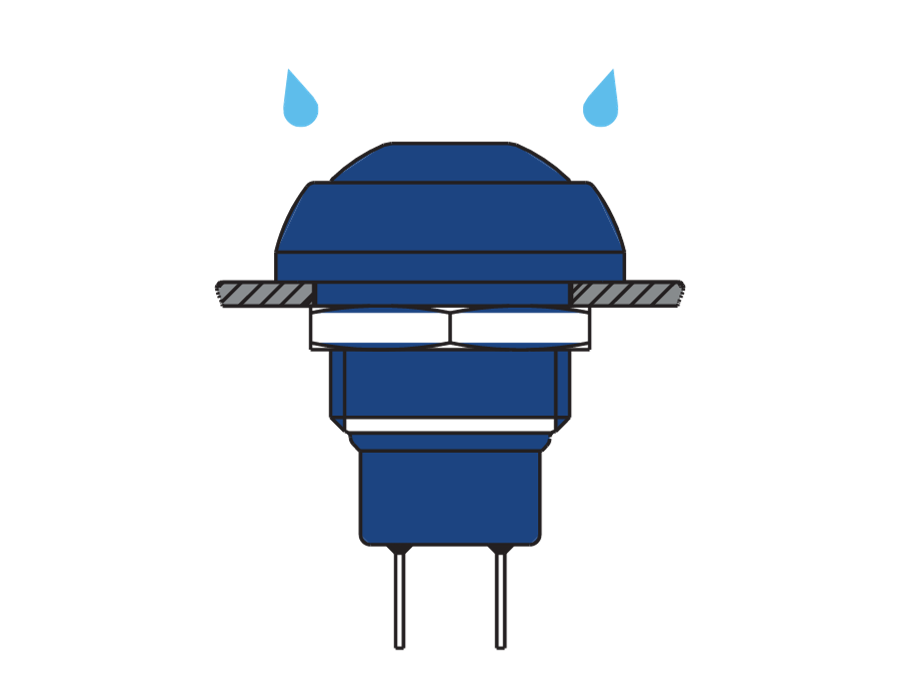

Fully Sealed

A fully sealed component goes one step further from the panel sealing and adds a sealing from the back. It is designed to prevent the ingress of contaminants from all sides. So, if you have a harsh environment where the risk of ingress is high and you want to ensure that if a panel sealing fails and ingress enters the application, the component will continue to be operational. This means that fully sealed HMIs are suitable for more demanding environments or safety-critical applications.

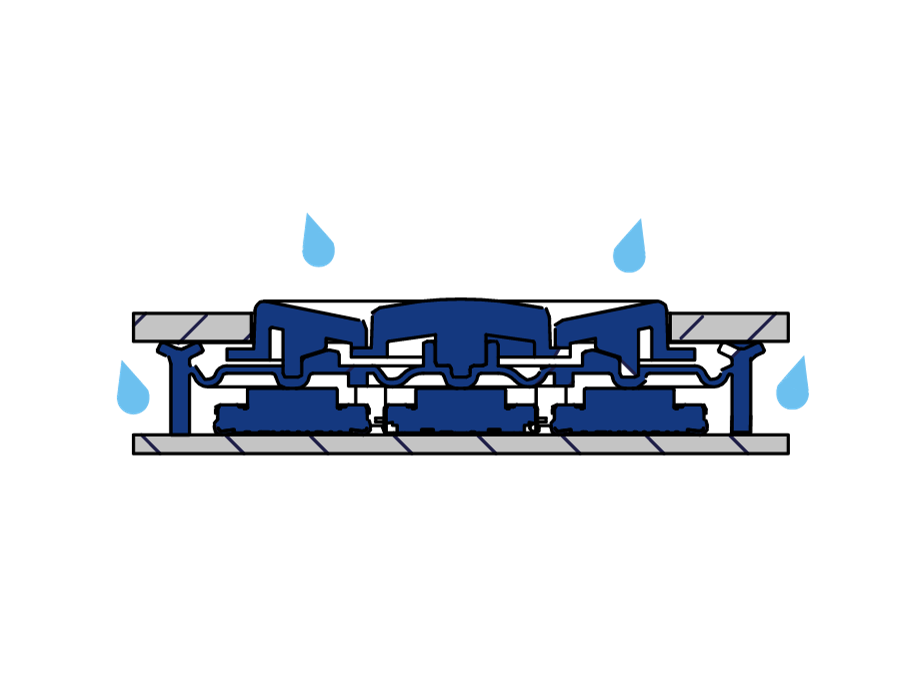

Super Sealed

The term “super sealed switch” doesn’t have a universally defined meaning and might vary depending on the manufacturer or context. However, it generally implies an even higher level of sealing and protection compared to a fully sealed switch. It can even go beyond standard sealing measures. At APEM we typically consider a solution super sealed when a fully sealed component is used with extra protection, e.g. a boot. But it can also mean enhanced sealing techniques or advanced materials to withstand rigorous testing, so the solution is suitable for extreme conditions, such as chemical industry and military equipment.

As you can now understand “panel sealed to IP67” and “fully sealed to IP67” mean different risk levels for your application and either one can become “super sealed” with adding further protection, such as a boot. It is therefore important to not just look at the IP rating but also the type of sealing, especially for safety-critical functions.