A classic switch has one input and one output. It can be NO (normally open) or NC (normally closed). A NC/NO switch has one input and two outputs and consequently 2 possible actions.

ONE SINGLE SWITCH FOR TWO OPERATIONS

With a NC/NO switch, there are two output types: one switching and another non-switching. This double function is interesting in many applications, but let’s take a concrete example:

Consider a construction excavator with a switch featuring NC, NO, and NC/NO functions controlling its hydraulic arm. In its normal state (NC), the switch keeps the hydraulic arm raised, maintaining a clear and safe workspace around the excavator.

When the operator activates the switch to NO, the hydraulic arm lowers to engage with the ground or materials, enabling digging or lifting operations.

The NC/NO function allows the operator to override standard operations for specialized tasks, such as operating auxiliary equipment attached to the arm, thereby optimizing the excavator’s utility across various construction tasks with a single control switch.

A HIGH SAFETY LEVEL

A NC/NO switch also offers a backup feature. You can confirm the correct functioning of the system and the device on which it is installed. This is a significant benefit in scenarios where safety is paramount (medical or military equipment).

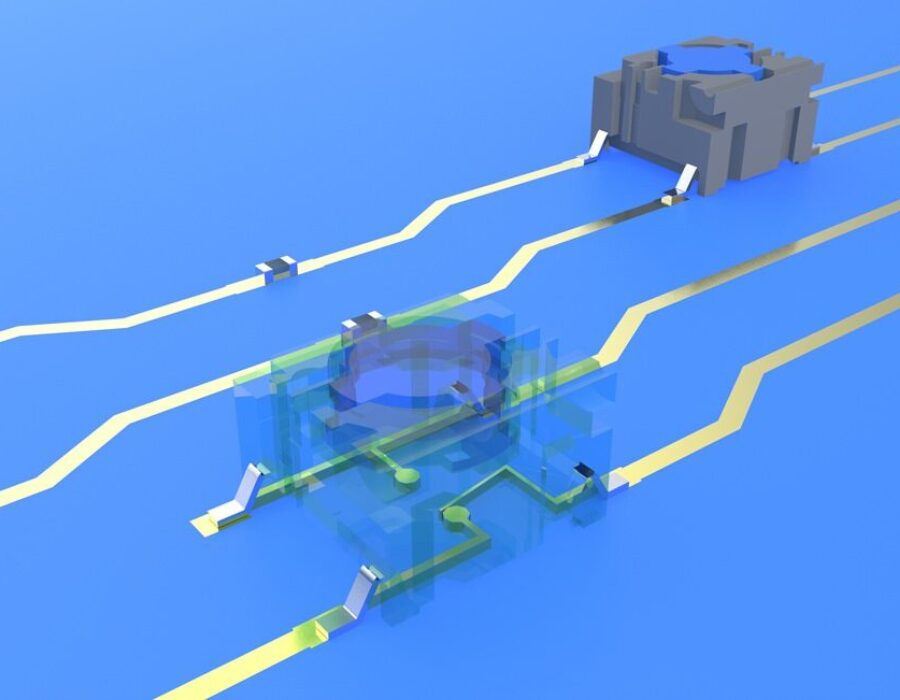

Miniaturizing this function is hard, that is why it is rare on the tact switch market. Our engineers have developed a specific dome shape allowing to keep the circuit closed when non-switching. The Multimec 5 series tactile switch is available with a NC/NO function and a life of 1 million cycles.

The default state of the circuit is Normally Closed (NC). In this state, current can flow freely. The circuit remains closed unless the switch is turned on.

DIFFERENT APPLICATIONS OF NC/NO PUSH BUTTONS

NC/NO buttons are essential in various devices for safety and operational efficiency. NC buttons ensure machines stop or remain inactive when triggered (e.g., emergency stops, safety interlocks). NO buttons allow operations to start or continue when pressed (e.g., machine start buttons, elevator call buttons). Their correct application is crucial for ensuring device safety and functionality across industries.

APEM offers a wide range of touch buttons and touch switches with NC/NO functionality:

NO/NC MOMENTARY PUSH BUTTON: DYNAMIC CONTROL AND EFFICIENCY

An NC/NO momentary push button combines Normally Closed (NC) and Normally Open (NO) functions in one device, reverting to its original state after release. It controls two circuits: it conducts electricity when unpressed (NC) and interrupts the flow when pressed (NO). These buttons are perfect for applications that need fast response times, like in industrial machinery and safety systems. They provide precise control, strong performance, and improved safety features.

Find more about the NO/NC momentary push button switch

LATCHING NC/NO PUSH BUTTONS: MAINTAINED FUNCTIONALITY ACROSS APPLICATIONS

Some push buttons stay in place until switched again, allowing continuous use without holding them down. The “set and forget” feature is useful when a consistent state is necessary. This feature can be helpful in lighting controls, security systems, and equipment with a steady output.

Latching NC/NO push buttons differ from momentary types as they do not revert to their initial state upon release. Instead of changing constantly, they stay in one state when activated. This feature simplifies operations and enhances safety by preventing accidental changes in critical settings. Latching NC/NO push buttons are versatile and ideal for many different uses. They are reliable and easy to use, making them perfect for situations where continuous control is needed.

Get in touch with an APEM expert to find the best pushbutton for your needs. You can also chat with us to learn how NC/NO switches can enhance your setups and functionality.