Choosing components for demanding applications is now more important than ever. Sophisticated devices are being deployed into harsh environments as military users adopt the latest technologies. Engineers need to provide reliability in the toughest conditions. To ensure that components can deliver the high performance needed, manufacturers use quality certifications known as military standards.

Ensuring compliance: how military standards shape product design and testing

There are military standards for all parts, components, and systems that are intended for use in defence equipment. A military standard describes all aspects of the product, from its physical design and the materials it is made of to the testing it must undergo and the performance it must deliver. The military specification provides a kind of shorthand that demonstrates that a product will perform well in tough conditions, making it easy for customers to select components for military equipment.

APEM’s quality system: a testament to NATO-listed manufacturing excellence

Our quality system allows APEM to be a NATO-listed manufacturer. This means that our production line has been assessed to ensure that we manufacture products according to a strict process and are fully traceable.

The Department of Defence (DOD) in the United States has established stringent criteria and comprehensive MIL-DTL testing protocols. A device that successfully completes these tests earns MIL-DTL certification. Yet, numerous products assert MIL-DTL certification without having been subjected to this strict evaluation. To confirm the authenticity of such claims, it is advisable to request the specific testing procedures and their outcomes.

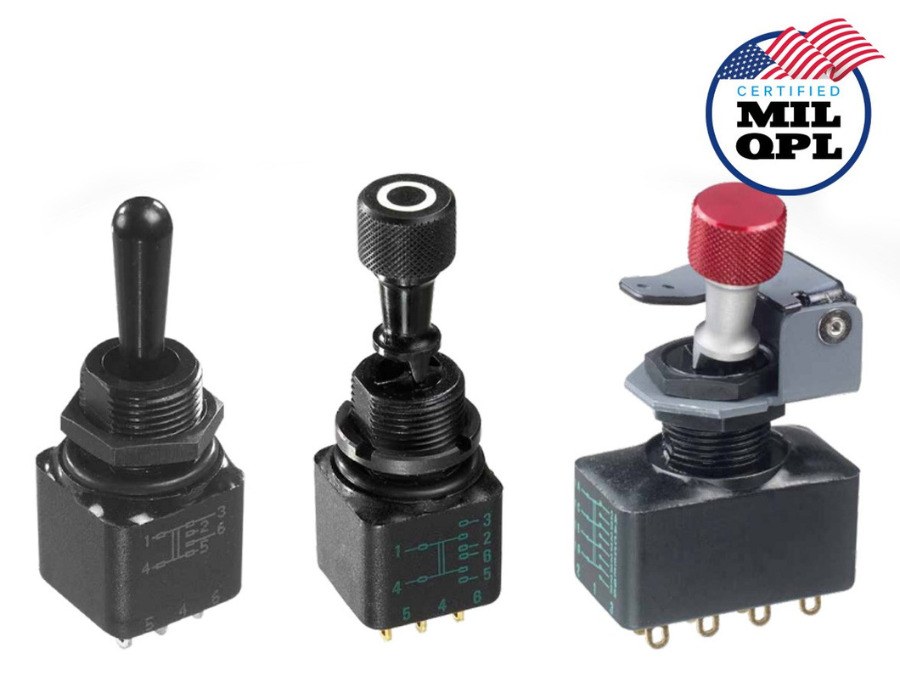

At APEM, our products are tested for MIL-DTL compliance and re-tested at every update of the standard. We offer a range of switches that comply with several certifications. Our range of switches is governed by standards MIL-DTL-3950 and -83731.

Products that comply with these standards are added to the Qualified Parts List and are described as QPL-listed.

MIL-DTL-3950 and MIL-DTL-83731 standards: what’s the difference?

MIL-DTL-3950 and MIL-DTL-83731 are two distinct military standards that specify requirements for different types of toggle switches used in military applications.

MIL-DTL-3950 focuses exclusively on environmentally sealed toggle switches, while MIL-DTL-83731 includes specifications for both sealed and unsealed toggle switches, addressing a wider range of military applications. Both standards play a crucial role in ensuring the durability and reliability of toggle switches in various military environments.

MIL-DTL-3950

This standard, officially titled “MIL-DTL-3950G, covers the requirements for environmentally sealed toggle switches. These switches are designed to withstand harsh environmental conditions, ensuring reliable operation in various military settings where exposure to elements like moisture, dust, and extreme temperatures is common.

MIL-DTL-83731

Known formally as “MIL-DTL-83731D, the standard outlines the general specifications for both sealed and unsealed toggle switches. The coverage of both sealed and unsealed types indicates a broader application scope, catering to different levels of environmental exposure and operational requirements in military equipment.

Local support for global standards: APEM’s US-based operations

APEM has a long track record of supporting some of the most advanced military programs in recent years, especially for ground vehicles, communication equipment and remote controllers. US-based customers can not only benefit from our extensive range of QPL-listed components, but also our US-based sales and technical team in California can provide local support for new and existing projects.

APEM, a history of support and innovation for the defenCe industry

APEM’s dedication to meeting and exceeding military standards in component manufacturing is evident in our commitment to quality, reliability, and performance. Our adherence to MIL-DTL certifications ensures that every product we offer, from switches to complex systems, is capable of withstanding the toughest conditions, providing our military clients with the confidence they need in their critical applications.

For a closer look at how APEM is advancing the defence industry with our innovative solutions, visit our dedicated defence industry page: