All outdoor applications and applications that stand near windows are exposed to ultraviolet light. Long-term exposure to UV light can damage your HMI. Therefore, you need to protect your application to ensure its safety and functionality.

Color fades

Fading colors are not nice to look at and make the application look worn down and cheap. Furthermore, any branding-related coloring will lose its effect. However, the most important issue is that it will become increasingly difficult to distinguish between color-coded functionalities, which means the safety of the operator and the machine can be in danger.

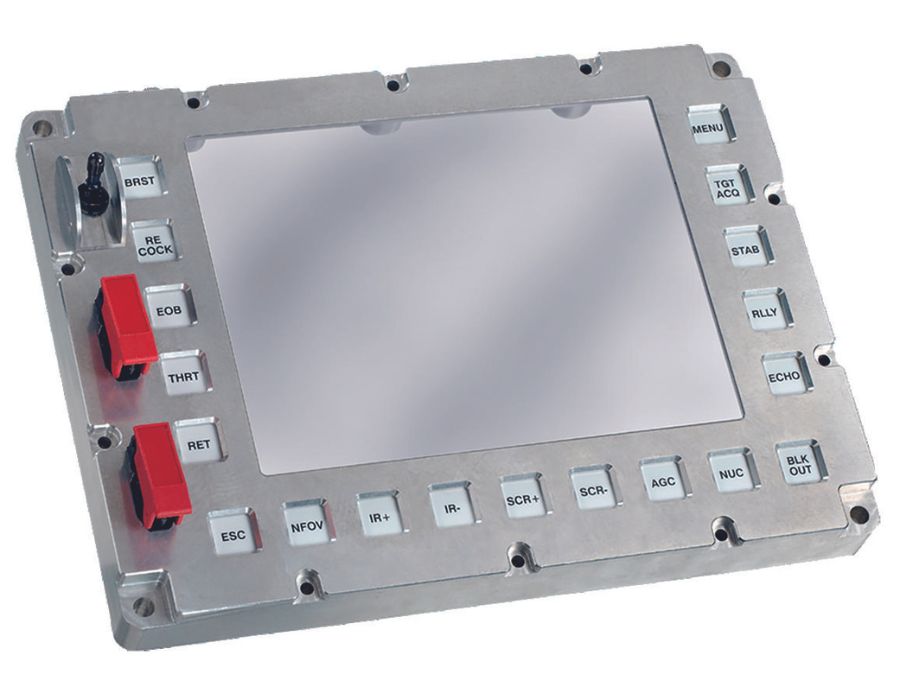

Markings fade or deteriorate

Ultraviolet light can make the ink fade and deteriorate to a point that it falls off. The operator will have to rely on their memory or guess where different functions are, which will bring the efficiency down and increase the risk of accidents.

Materials deteriorate

Beyond the fact that it does not look good when the control panel gets flaky or a layer can peel off, it can also mean that the protection against ingress is reduced. Rubber is especially vulnerable to UV light, so the sealing of your joystick can roughen and break. The same is true for the membrane HMIs that can delaminate.

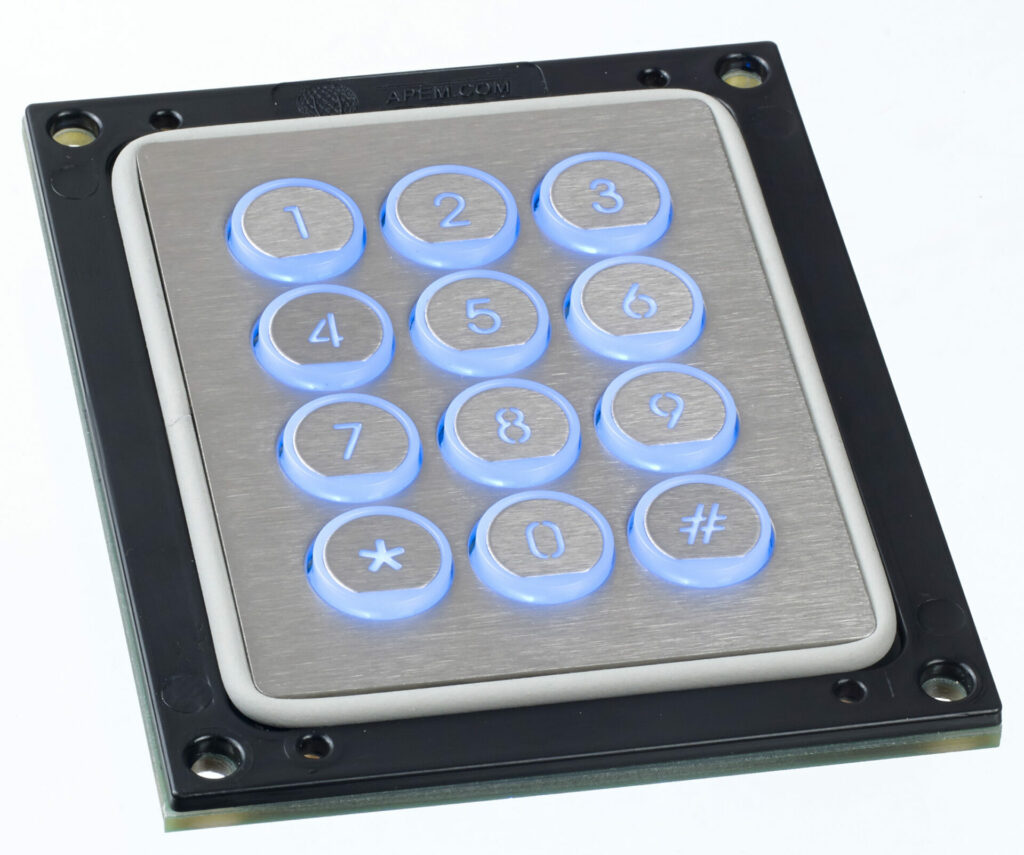

You need to pick the right materials or cover the vulnerable materials with a special top coating that can protect them. The best materials to use are:

– Hard plastic

– Glass

– Metal – especially when treated

Regarding markings, engraving is a good idea for long-lasting markings. So is back molding. You can also cover the ink with a special coating to make them more long lasting. APEM is used to serve many markets, including public use, agriculture, and construction markets, with solutions that can handle exposure to UV light.