Protecting your Human-Machine Interfaces (HMIs) from autoclaving and other harsh cleaning techniques is essential in critical environments like cleanrooms, pharmaceutical manufacturing, food processing, or aseptic processing and testing. Designing HMIs that can withstand regular sterilization and harsh cleaning cycles involves understanding the unique requirements of sterile environments and implementing design strategies that maintain operational efficiency and durability.

What is the Difference between Clean and Sterile?

The term “clean” generally refers to being free from dirt, impurities, or pollutants from surfaces or objects. Cleaning reduces the number of microorganisms to a safer level but does not necessarily eliminate all forms of microbial life. On the other hand, sterilization refers to the complete elimination of all forms of microbial life, including bacteria, viruses, spores, and fungi.

Cleanrooms vs Sterile Environments

While the vast majority of cleanrooms are likely considered clean, not all are considered sterile. So, what is the difference between a sterile and clean room? A cleanroom is designed to control particulate contamination, maintaining a specific level of cleanliness by regulating airborne particles through filtration systems. This setting is crucial in industries like electronics and pharmaceuticals, where particle contamination can significantly impact product quality.

A sterile environment aims to eliminate all forms of microbial life. Sterility is mandatory in areas requiring the absolute absence of microbes, such as in surgical rooms or in the manufacturing of sterile medical devices. For HMIs in these settings, it’s vital to design interfaces that resist contamination and withstand rigorous cleaning or sterilization without degradation, ensuring both functionality and compliance with environmental standards.

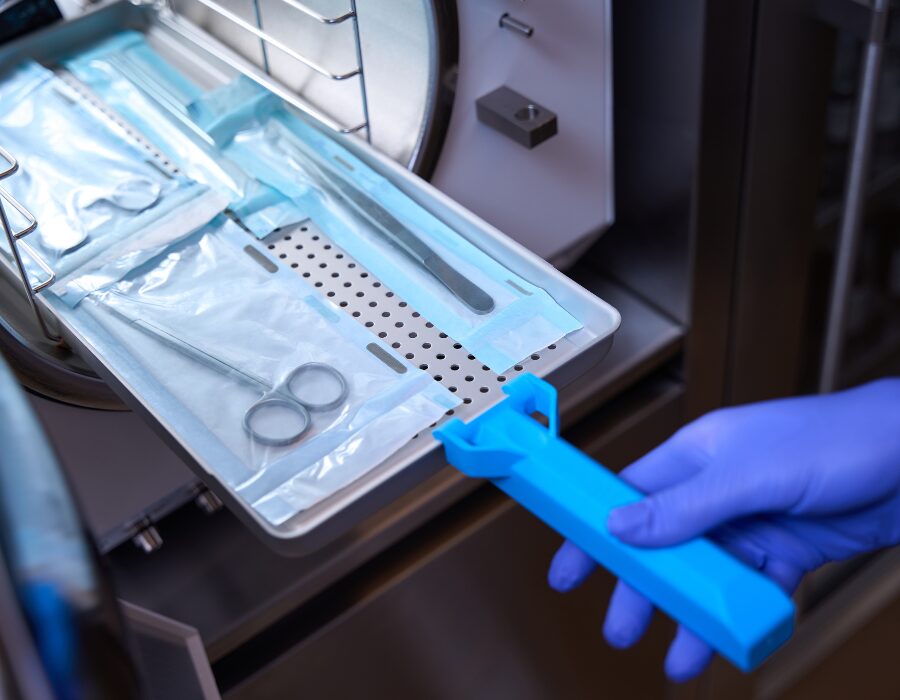

How do you sterilize HMIs and other Technical Equipment?

The choice of sterilization method is critical and must be compatible with the equipment to prevent damage. Regular sterilization processes are intense due to their objective of eliminating all forms of microbial life. Options include heat sterilization through autoclaves or vapor, chemical sterilization using special cleaning agents, radiation sterilization, and UV light for surface disinfection. Technical equipment, especially in medical and laboratory settings, must be constructed to withstand numerous harsh cleaning and sterilization cycles without degrading in function or integrity.

HMI Designs Tips for Sterile Environments

Designing HMIs for sterile environments requires a special focus because they should not only withstand harsh cleaning cycles but also feature effective water-resistant sealing. Ensuring HMI panels are effectively sealed and gasketed is essential to eliminating any potential gaps or openings that might lead to contamination. It’s important to use gaskets of exceptionally high quality, made from materials like silicone or elastomer, to guarantee that technical equipment is fully sealed. HMI panel surfaces need to be designed smoothly to simplify cleaning and stop particles from gathering. The design should minimize grooves or crevices to prevent particle trapping, ensuring easy cleaning and reduced microbe dispersion. Furthermore, the surface should contain smooth stainless steel or special plastics that prevent bacterial growth. To further reduce the development and spreading of microbes, HMI panels can be treated with antimicrobial coatings.

Main Applications

- Cleanrooms

- Pharmaceutical Manufacturing

- Sterile Manufacturing, Processing & Testing

- Laboratories

- Surgical Rooms

- Food Processing

A Selection of APEM Products suitable for Cleanrooms and Sterile Environments

At APEM, we are committed to keeping abreast of the latest technological developments to deliver superior services. Rely on a professional team that can help you deliver HMIs for cleanrooms and sterile environments.