Human-Machine Interfaces (HMIs) are critical in many industrial applications, where the demand for stringent quality standards is paramount.

APEM has developed and implemented procedures and related processes which have been assessed by the IECQ Certification Body issuing certificate and found to comply with the applicable requirements of the IECQ Approved Process Scheme which is in accordance with the Basic Rules IECQ 01 “Rules of Procedure”, IECQ 03-1 “IECQ General Requirements for all Schemes” & IECQ 03-2 “IECQ Approved Process Scheme” of the IEC Quality Assessment System for Electronic Components (IECQ), and in respect of standard(s) or specification(s):

KEY ASPECTS OF IECQ/CECC STANDARDS

IECQ/CECC standards are comprehensive, covering various quality norms and testing methodologies. These standards ensure that electronic components undergo rigorous testing to meet performance and reliability criteria.

Key aspects include detailed specifications for components, standardized testing methods, and strict certification processes. These elements are designed to ensure that components are robust and reliable for use in critical applications. The IECQ/CECC certification process involves thorough assessments, providing manufacturers and clients with confidence in the products’ quality.

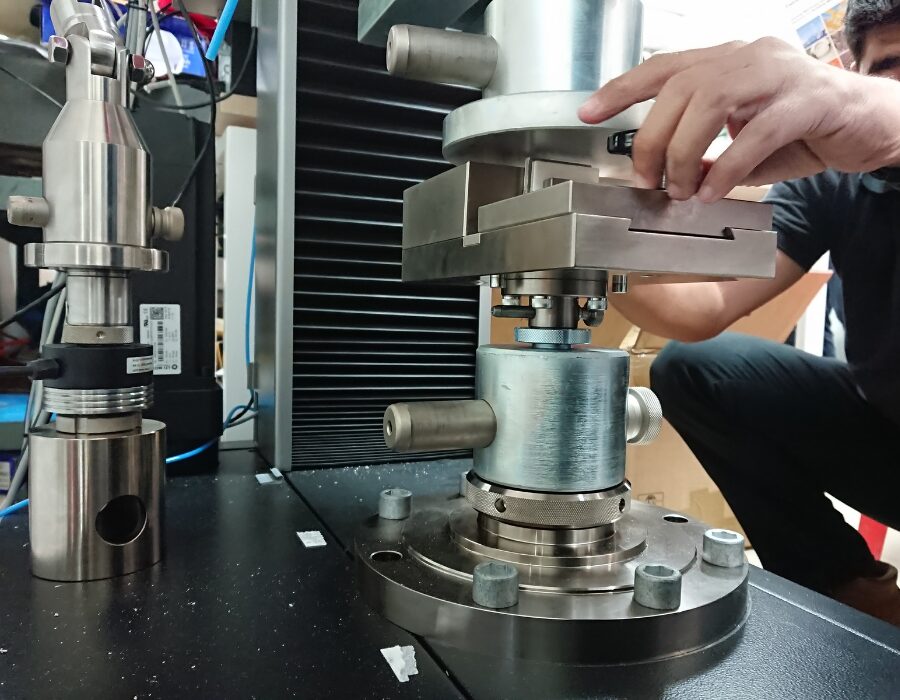

Example: Testing to assess the climatic category and stability class of HMIs:

- Components must be qualified for specific climatic categories, defined by temperature ranges and humidity resistance tests.

- Components must meet defined stability classes, which group together stability requirements for different tests. These classes ensure that components maintain their performance and reliability over a long period and under demanding conditions of use.

HMIs that comply with the IECQ/CECC standard are also subject to periodic inspections. These inspections can be scheduled every 3 months, 12 months or 36 months, depending on the specific requirements of the product.

BENEFITS OF IECQ/CECC CERTIFICATION FOR BOTH MANUFACTURERS AND CLIENTS

IECQ/CECC certification offers significant benefits to both manufacturers and clients. For manufacturers, the certification process ensures that their products meet high quality standards, providing a competitive edge in the market. Manufacturers can also guarantee that their products meet stringent standards.

Moreover, this compliance simplifies the regulatory approval process, facilitating smoother market entry and reducing compliance costs. Thus, technical barriers are reduced, making it easier to access the international market.

For clients, IECQ/CECC certification offers assurance that the products they use comply with international standards. This certification helps clients make informed decisions, ensuring that they select reliable components for their applications.

APPLICATIONS OF IECQ/CECC STANDARDS IN THE MILITARY SECTOR

IECQ/CECC standards are widely applied across multiple industries and especially the military sector. Toggle switches used in the military sector by international customers need to be IECQ/CECC-certified products. Our products comply with CECC 96000 standard. Our military-qualified toggle switches are governed by the CECC 96401-001, 96201-005 and 96201-008 specifications.

SPOTLIGHT ON CECC-CERTIFIED APEM PRODUCTS

The IECQ/CECC certification is present on APEM products and especially APEM toggle switches. These products are designed to meet the highest standards of quality and reliability, making them suitable for demanding applications. By choosing APEM’s IECQ/CECC-certified products, clients can ensure compliance with international standards, enhancing the reliability of their systems.

11000–12000 series

CECC 96 201-005 {Ed2, 1995} Lever switch

CECC 96 201-008 {Ed2, 1995} Lever switch

13000 series

CECC 96 401-001 {Ed1, 1988} Push button switch

5000 series

CECC 96 201-007 {Ed2, 1995} Lever switch

12000X778 series

CECC 96 201-005 {Ed2, 1995} Lever switch

CECC 96 201-008 {Ed2, 1995} Lever switch

13000X778 series

CECC 96 401-001 {Ed1, 1988} Push button switch

3500 series

CECC 96 201-005 {Ed2, 1995} Lever switch