APEM stands at the forefront of Human Machine Interface (HMI) technology, specifically catering to special vehicles and various other sectors such as medical and public environment. However, the term “HMI” within our domain transcends the conventional perception of screens or digital interfaces. At APEM, HMIs embody the tactile and physical aspects of machine control, encompassing switches, joysticks, and keyboards. These are not merely components, but the key elements of interaction between humans and off-road vehicles, enabling control and activation of these machines in the most demanding environments.

What is an HMI?

If we attempt to provide a generic definition of an HMI, we would say a Human Machine Interface serves as the bridge between a user and a device, system, or machine, facilitating interaction and control.

In the broadest sense, HMIs can range from digital touchscreens found in consumer electronics to the physical controls in industrial machines or off-road vehicles. The purpose of an HMI is to provide an intuitive, efficient, and safe means for users to manage operations. They are crucial in ensuring that the user’s commands are translated into actions by the machine with feedback, making operations smoother and more predictable.

Here are some Human-machine interface examples you can find at APEM :

What is an off-road vehicle?

Off-road vehicles (or special vehicles) are engineered to conquer the unforgiving and varied terrains that lie beyond the smooth pavements of urban landscapes. These specialized machines face critical and harsh conditions across a spectrum of challenging environments, including construction sites, mines, defense operations, agricultural fields, and material handling tasks. Unlike standard vehicles, off-road machinery must perform reliably under extreme conditions such as mud, dust, water, significant temperature variations, and rugged terrain.

The importance of reliable HMI solutions in off-road vehicles

In the challenging environments where off-road vehicles operate, the reliability of HMIs cannot be underestimated.

At construction sites, these vehicles navigate through debris, heavy loads, and constant vibrations. Mines demand equipment that can withstand abrasive dust and significant mechanical stress. In defense scenarios, reliability in diverse environmental conditions can be a factor in mission success and personnel safety. Agricultural applications require machinery that can operate effectively across different soil types and weather conditions, while material handling vehicles must be versatile and robust enough to manage heavy and varied loads in warehouses as well as outdoor settings.

The demanding nature of these environments is a significant factor in the durability, reliability, and functionality of off-road vehicles. These conditions underscore the necessity for high-quality Human Machine Interfaces (HMIs), as the control and interaction between the operator and the machinery are pivotal for operational efficiency and safety. This challenging backdrop highlights the importance of specialized HMIs that can withstand the rigors of off-road conditions, ensuring that operators maintain precise control over their machinery, regardless of the obstacles they face.

« A reliable HMI ensures that operators can control the vehicle effectively, regardless of external conditions, safeguarding both the operator and the vehicle. The tactile feedback and durability of physical HMIs are indispensable in scenarios where precision and reliability are non-negotiable. »

Criteria to consider when selecting an HMI for your off-road vehicle

Choosing the right HMI for a professional special vehicle involves several critical considerations:

- Durability: The HMI must withstand the environmental stresses of off-road use.

- Ergonomics: It should offer comfort and ease of use, even in demanding conditions.

- Responsiveness: Quick and accurate response to user input is essential for safety and efficiency.

- Customizability: The ability to tailor the HMI to specific vehicle and user needs.

- Integration: Seamless integration with the vehicle’s systems is crucial for optimal performance.

It’s the combination of all these criteria that make the difference and provide the user with a safe, comfortable, and intuitive handling experience.

What industries are APEM HMIs designed for?

APEM’s extensive expertise in human machine interface (HMI) technology encompasses several critical industries, ensuring optimal performance and reliability under the most demanding conditions. Here’s a closer look at how APEM caters to each sector:

HMIs for Defense

In the defense industry, where equipment reliability can be a matter of life, APEM provides rugged, durable HMI solutions designed to withstand extreme conditions. From panel switches that can endure the vibrations and shocks of armored vehicles to joysticks that offer precise control for unmanned systems, our products ensure operational efficiency and safety in the most critical missions.

HMIs for Construction

Construction equipment requires HMIs that can withstand dust, debris, and repetitive use. APEM’s ergonomic switches and controls are built to resist the harsh conditions found on construction sites, ensuring machinery remains operational and reliable, minimizing downtime and enhancing productivity on projects ranging from skyscrapers to infrastructure development.

HMIs for Material Handling

Efficiency and precision are essential in material handling, where APEM’s HMI solutions like ergonomic joysticks and responsive panel switches play a vital role. Our products help improve the control of forklifts, conveyor systems, and automated warehouse vehicles, facilitating smoother operations, reducing human error, and increasing safety in logistics and warehouse settings.

HMIs for e-TRANSPORTATION

As the automotive industry evolves towards electric and autonomous vehicles, APEM is at the forefront of providing innovative HMI solutions that enhance user interaction and safety. Our components are designed for the new era of mobility, offering intuitive controls for electric vehicles (EVs), charging stations, and public transport.

HMIs for Agriculture

In agriculture, where machinery must perform reliably over a long period of time and in varying conditions, APEM’s HMIs ensure precise control and durability. Our solutions, including rugged joysticks and switches, enhance the functionality of tractors, harvesters, and drones, facilitating efficient farming practices and contributing to sustainable agriculture.

HMIs for Medical and Healthcare

The medical industry demands HMIs that are not only reliable but also capable of precise operation. APEM provides switches, joysticks, and panel solutions for medical devices, ensuring they meet the strictest standards for cleanliness, accuracy, and reliability. Our products are used in applications ranging from laboratory equipment to diagnostic devices, contributing to patient care and health outcomes.

HMIs for Public Environment

APEM’s HMIs enhance the accessibility and usability of equipment in public spaces, such as vending machines, lifts, and access terminals. Our durable and intuitive interfaces ensure that services remain accessible and easy to use for the general public, contributing to a more inclusive and convenient urban environment.

Through our dedication to quality, innovation, and customization, APEM serves these diverse industries with HMI solutions that meet their unique challenges, driving efficiency, safety, and reliability in operations worldwide.

What types of HMIs can you find at APEM?

APEM’s catalog of HMI solutions is extensive and highly customizable. While performance is the common denominator for all the solutions that leave our factories, each product or solution is unique, a perfect reflection of the customer’s specifications. Our product range includes:

Panel switches

Our panel switches are designed with a focus on durability and ergonomic efficiency, making them ideal for environments that demand reliability and ease of use. With options for customization in various factors like actuation force, tactile response, and aesthetic design (including customizable legends and backlighting), these switches are versatile enough for applications from heavy machinery controls to medical devices.

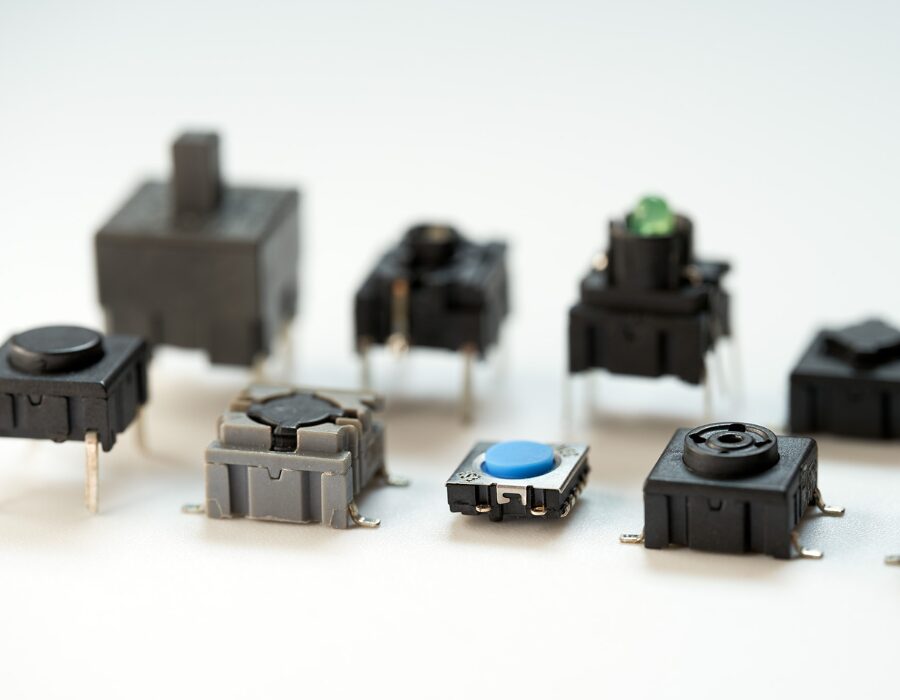

PCB Switches

APEM’s Printed Circuit Board (PCB) switches are compact, efficient, and designed for seamless integration into a variety of electronic assemblies. These switches offer customizable actuation and response characteristics and are engineered for reliability in applications requiring precise control inputs. Their small footprint makes them particularly suitable for applications where space is at a premium, such as handheld controls and compact instrument panels. Depending on your specifications, you can choose between an APEM or MEC solution.

LED Indicators

Our LED indicators provide clear, long-lasting visual feedback for machinery and equipment status. Available in a wide range of colors, brightness levels, and sizes, these indicators are designed for high visibility and low power consumption. They are ideal for use in control panels, dashboards, and portable equipment, ensuring operators can quickly assess system statuses at a glance, even in harsh or low-light conditions.

Joysticks

APEM’s joysticks, from fingertips to handgrips, are engineered for precision and durability, offering smooth and intuitive control for a wide array of applications. From simple two-axis controls to more complex multi-axis configurations, our joysticks provide nuanced command over machinery, vehicles, and electronic systems. Features such as adjustable resistance, programmable functions, and haptic feedback can be customized to meet the specific needs of the application, whether it’s for industrial machinery, medical equipment, or simulation and gaming technologies.

Panel Solutions

Our panel solutions integrate various HMI components into a single control interface, tailored to the specific requirements of our clients’ projects. These comprehensive solutions can include any combination of switches, joysticks, displays, and indicators, all mounted within custom-designed panels. This approach does not only streamlines the design and manufacturing process, but also ensures that the final product offers seamless functionality and aesthetics. Panel solutions are ideal for applications requiring a bespoke control interface, from specialized vehicle dashboards to complex industrial machinery and defense systems.

APEM’s ability to provide such a wide array of HMI components and complete solutions emphasizes our position as a leader in the field. By offering the widest customization possibilities, coupled with our integrated manufacturing process, we ensure that every product does not only meet but exceeds the stringent quality and reliability standards required by our diverse clientele.

Why are our HMIs ultra-reliable for professional applications?

APEM’s commitment to manufacturing ultra-reliable human machine interfaces (HMIs) is founded on a holistic approach to quality, innovation, and customer collaboration. Our HMIs are engineered to excel in professional applications where performance and durability are non-negotiable. Here, we delve into the core aspects that contribute to the unmatched reliability of our HMI solutions.

Advanced Materials and Design

At the heart of APEM’s reliability is our selection of advanced materials and thoughtful design processes. We choose materials that offer superior durability, resilience to environmental conditions, and long-term performance. Our designs incorporate ergonomic principles and intuitive layouts to enhance user experience and reduce the likelihood of operator error, further ensuring the reliability of operations.

Rigorous Testing and Quality Assurance

Every HMI component we produce undergoes stringent testing procedures that simulate real-world conditions and stresses. These tests encompass environmental challenges (such as extreme temperatures, moisture, and dust), mechanical stress (including vibration, shock, and wear testing), and long-term operation to ensure that our products can withstand the rigors of professional use. Our comprehensive quality assurance process, which includes both pre-production testing and ongoing monitoring, guarantees that each product maintains the highest standards of reliability and performance.

Customization and Integration Expertise

APEM’s ability to offer customized solutions extends beyond mere aesthetic adjustments. We work closely with our clients to understand the specific demands of their application, allowing us to tailor the functionality, feedback, and user interface of our HMIs to meet these unique requirements. This customization ensures optimal integration into the clients’ systems, further enhancing reliability by minimizing compatibility issues and optimizing performance.

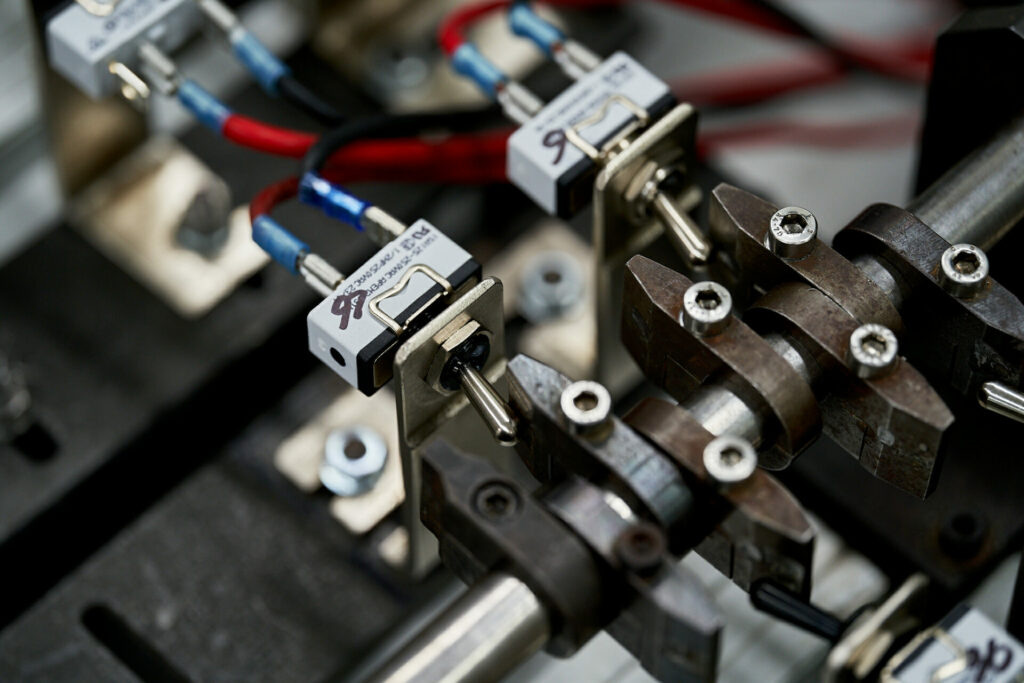

Integrated Manufacturing

Our integrated manufacturing process, which covers every stage from design and prototyping to production and quality control, ensures a seamless transition from concept to final product. This control over the manufacturing process allows us to maintain the highest quality standards and react quickly to any potential issues before they affect our clients. Whether it’s upgrading existing machinery or designing a new system from the ground up, APEM’s comprehensive capabilities ensure your project’s success.

Unmatched portfolio and customization capabilities: the APEM difference

APEM distinguishes itself within the human-machine interface market not only through the quality of its products but also through the breadth and versatility of its offerings. We are uniquely positioned as the only provider capable of delivering such a comprehensive range of HMI solutions. From individual components like panel or PCB switches and LED indicators to complex joysticks and fully integrated panel solutions, our portfolio covers the entire spectrum of HMI needs.

Our extensive range of products is matched by unparalleled customization options. Understanding that each application has its specific requirements, we offer our clients the freedom to tailor our products to their exact needs. Whether it’s a minor adjustment to a joystick or a fully customized panel solution, APEM’s engineering teams work closely with clients to develop precise solutions that meet their operational demands.

APEM’s commitment to offering the widest range of customization possibilities, combined with our integrated manufacturing approach, sets us apart in the industry. We are not just a supplier; we are a partner dedicated to delivering HMI solutions that stand the test of time.