Choose robust materials

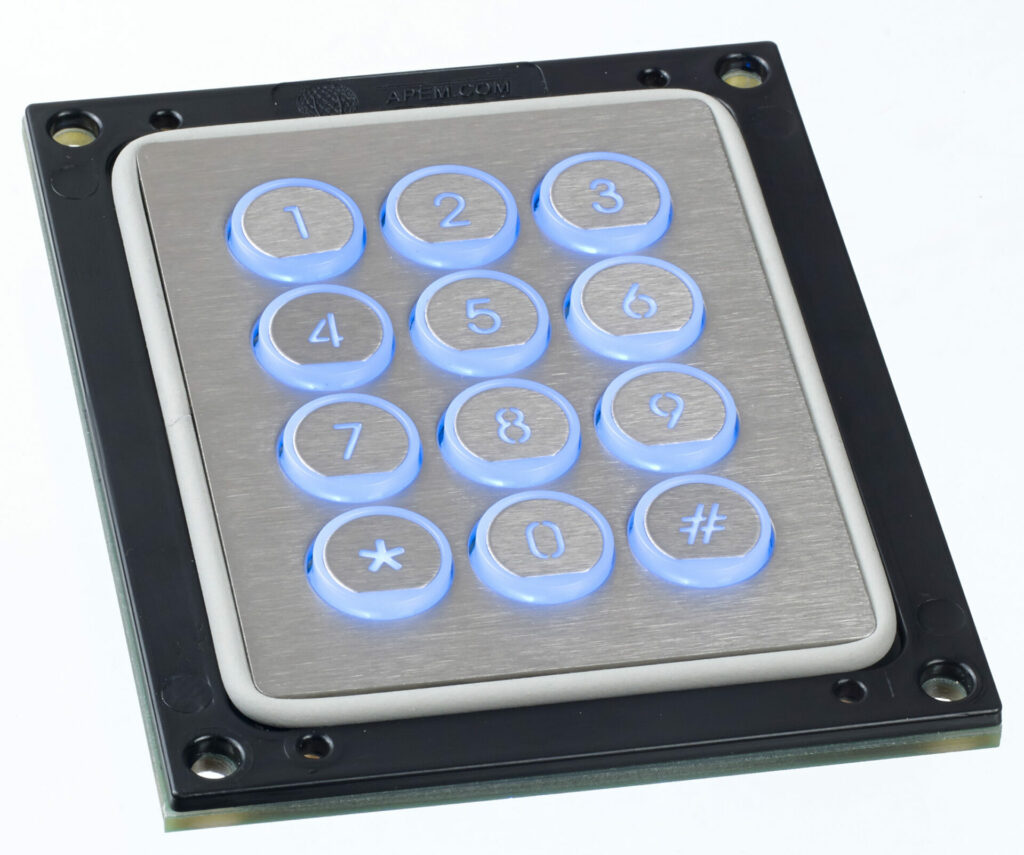

Opt for products and solutions that can withstand at least the IK08 level of impact. Metal buttons and a metal front panel provide increased durability and resistance to vandalism.

Minimize gaps and secure components

Design your HMI with as few and small gaps as possible to prevent tampering. Ensure that keycaps are larger at the bottom than at the top, so they cannot easily fall out or be removed.

Utilize anti-graffiti paint

Apply special anti-graffiti paint for markings on the HMI. This ensures that important labels and instructions remain visible, even if someone attempts to deface or damage them.

Use heat-resistant plastic for illumination

When incorporating illumination in your HMI, choose heat-resistant plastic materials. This ensures that the lighting components can withstand high temperatures without compromising functionality or safety.

Design for intuitive use

Create an intuitive design that simplifies the user experience. Use illumination, finger guides, and clear markings to guide users through the interface, reducing the likelihood of accidental damage caused by frustration or haste.

Ensure tactile feedback

Incorporate elements that provide tactile feedback, confirming the activation of buttons or controls. This feedback helps users feel assured that their actions have been registered without the need for excessive force or repeated attempts.

Protecting your HMI against vandalism is important for several reasons

- Application usage scenarios:

HMIs can be used in public spaces with minimal supervision, where they may be accessed by thousands of people daily. Additionally, in emergency situations, they might be used by individuals under stress or in a hurry. Protecting the HMI ensures its functionality remains intact despite mishandling or excessive force. - Insurance policy for emergency situations:

in cases where HMIs, such as emergency stop buttons, are rarely needed but critical for safety, protecting them from vandalism acts as an insurance policy. It ensures that these functions will be operational when they are required most. - Extended lifespan and cost savings:

by implementing protective measures, you can extend the lifespan of your HMI. Robust materials and design choices reduce the need for frequent repairs or replacements, resulting in cost savings over time.

Does APEM offer anti-vandal and shock resistant products and solutions?

Yes, APEM provides a range of anti-vandal products and solutions. We understand the importance of robust and tamper-proof HMIs. Our products undergo testing for IK ratings and other relevant tests to ensure their durability and resistance to vandalism. Contact us to explore our offerings and find the right solution for your needs.