At the beginning of the 20th century, many innovations related to electricity were patented due to the rapid development in this field. In 1916, toggle switches were created. The success of this product led to further innovations and in the 1950’s, APEM was created thanks to a specific patent to improve the life expectancy of toggle switches. A success that has not been forgotten, toggle switches remain as one of our most popular product lines today!

What are the different types of toggle switches?

At APEM, we offer various types of toggles. Our most common form of this is the toggle switch panel. With this, several options can be integrated, such as: 3 or 4 positions, momentary or alternate – your switch can be held down or return to its original state after being released – and protected by our guards or sealing boots accessories. Thanks to numerous rating, sealing, and lever finish options, APEM provides robust toggles for any application and offers the reliability of worldwide recognized certifications such as CECC, UL, CSA, VDE, NF.

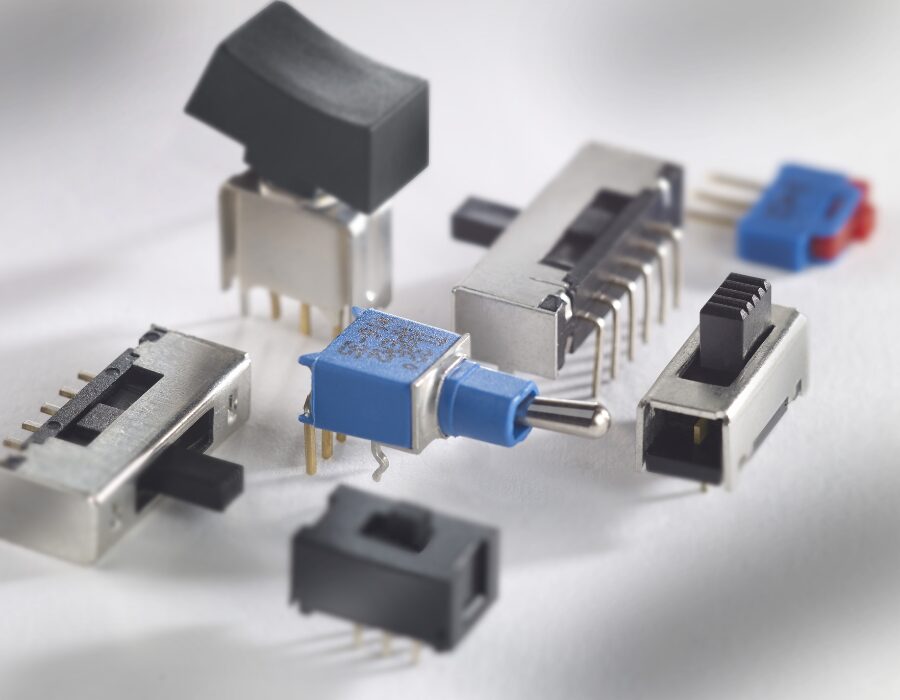

For low intensity applications, we have the PCB-mounted toggle switches which is in a smaller format. They are also a wise choice when your control panel requires many switches to control electronics. Installation with the circuit board simplifies assembly and improves safety, as there is only one connector to plug in. PCB switches are often more compact than panel switches, making them an excellent choice when space is limited. This human-machine interface uses a mechanical lever or handle mechanism to activate the switch. They can have two to three positions. The latching version gives the operator an easy visual indication of the switch’s status, providing additional safety. With these various features, toggle switches are very popular products offering several benefits to their users.

Why are we still using toggle switches? Why are they so popular?

To be indispensable in various applications, APEM toggles offer many advantages to meet different needs. One of these is the clear command status when the lever is tilted to one side or the other. This allows the operator to immediately check the toggle position at a glance without effort. In addition, their ergonomic design can be tailored to provide a seamless user experience, enabling blind operation with ease. With a plethora of safety options such as lockers and switch guards, toggles ensure secure operation, especially in critical and hazardous environments. Above all, knowing their long lifespan and watertight contacts, their reliability and robustness are unmatched, making them the ideal solution for outdoor use.

Interestingly, this solution has transcended its usual function to become a decorative object, particularly sought after for industrial design enthusiasts looking to infuse their homes with a touch of style.

Fun fact: they became very popular on platforms like Pinterest during the COVID-19 crisis, showcasing their enduring appeal and versatility.

What are the most common applications for toggles?

Speaking of versatility, our team of experts has provided a single solution to meet the needs of vastly different applications:

- Control panels

- Belly boxes

- Crane operator control panels

- Remote controls

- Construction equipment

- Material handling machinery…

- …and many more